The material used is propritary, the small

pads were bonded to an area to increase

the surface ware.

|

|

|

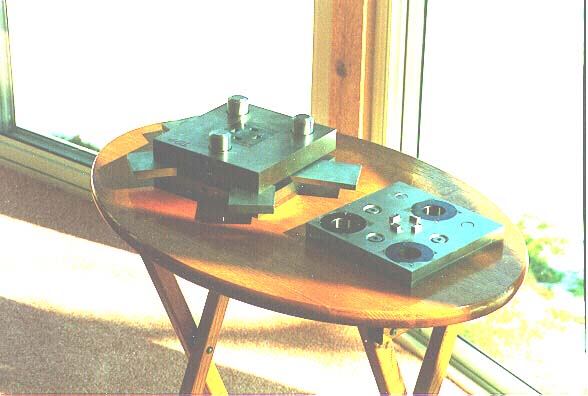

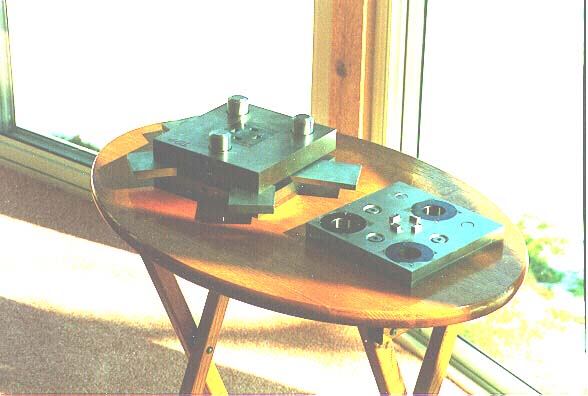

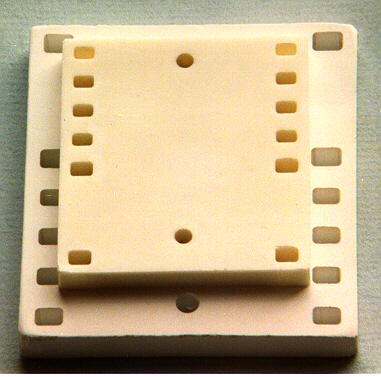

This tooling produced four (4) ware pads at a time. The material used is propritary, the small pads were bonded to an area to increase the surface ware. |

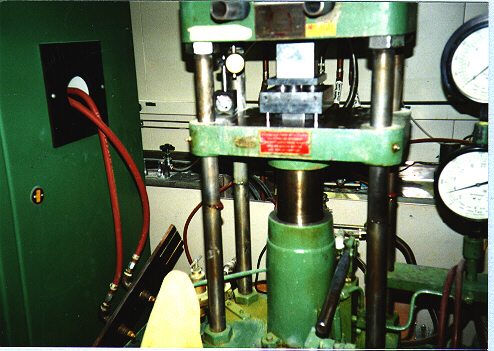

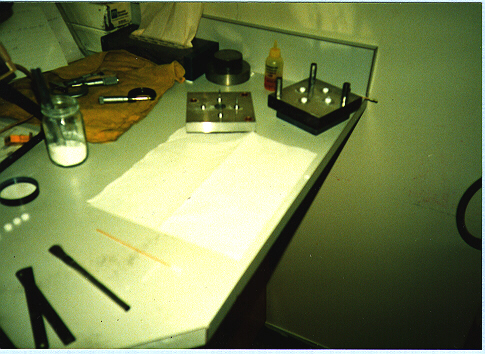

The die filled with Zirconia powder. |

Tooling compression using a hydralic press. |

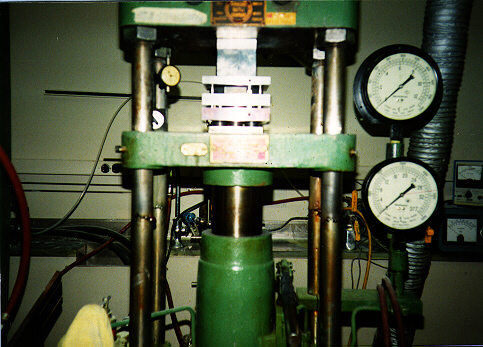

Compressed rollers being extruded from the die. |

Rollers ready to be removed from tooling. |

|

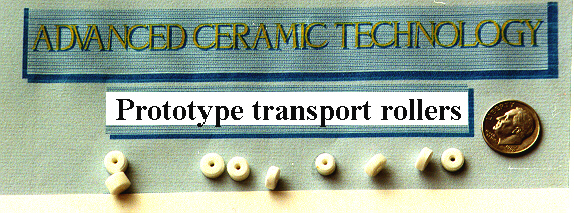

Prototype mold tooling used to produce four (4) small rollers with a center hole. |

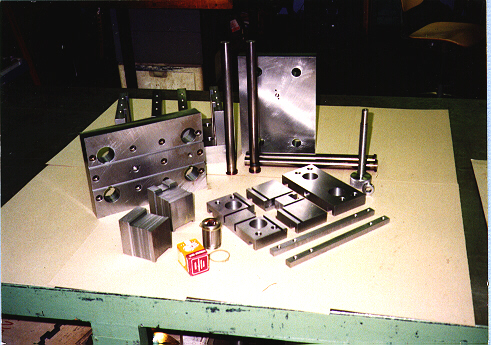

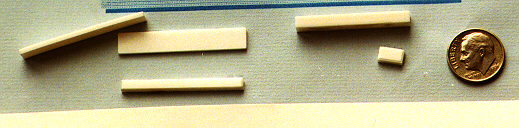

Components of the molding machine. |

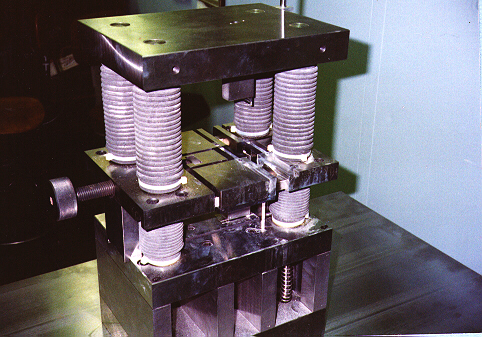

A prototype molding machine built to mold perforator punches. |

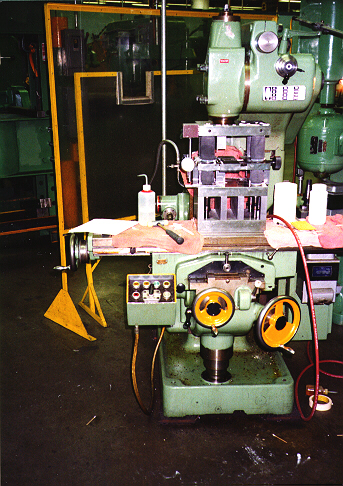

Prototype molding machine set up in a milling machine. The knee of the milling machine was used to compress and remove the molded parts. |

Prototype molding machine |

| Prototype molded parts from this machine are used as perforators with superior ware functions. |

A molded part to be used for a perforating die. |

A molded part before and after sintering. |

Molded parts to improve surface ware. |

Molded prototype perforating dies and parts to improve surface ware. |

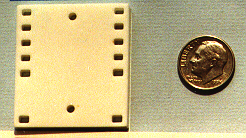

The following parts were molded using a powder metal cold press. The coin in the photos is a dime.

Cold pressed zirconia ceramic parts. |

Cold pressed zirconia ceramic gear. |

Cold pressed zirconia ceramic part. |

Cold pressed zirconia ceramic ring. |