We are equipped with tools such as PATRAN, ARIES, NASTRAN, ABAQUS, and FLOTHERM to perform following analysis:

- Stress and Displacements analysis of load carrying frames and machine elements

- Model the Motion of paper/media through 2-roller nips

- Model the flow of air in a complete product (printer, copier, etc) and determine optimum configuration (based on thermal management issues) of the system

- Model the sheet metal bending process and evaluate the amount of spring-back.

- Perform Stress and Vibration analysis using simulated shipping loads

- Study and evaluate thermal cooling concepts in electronic and mechanical sub-systems

- Crash Simulation using non-linear FEA for understanding packaging issues.

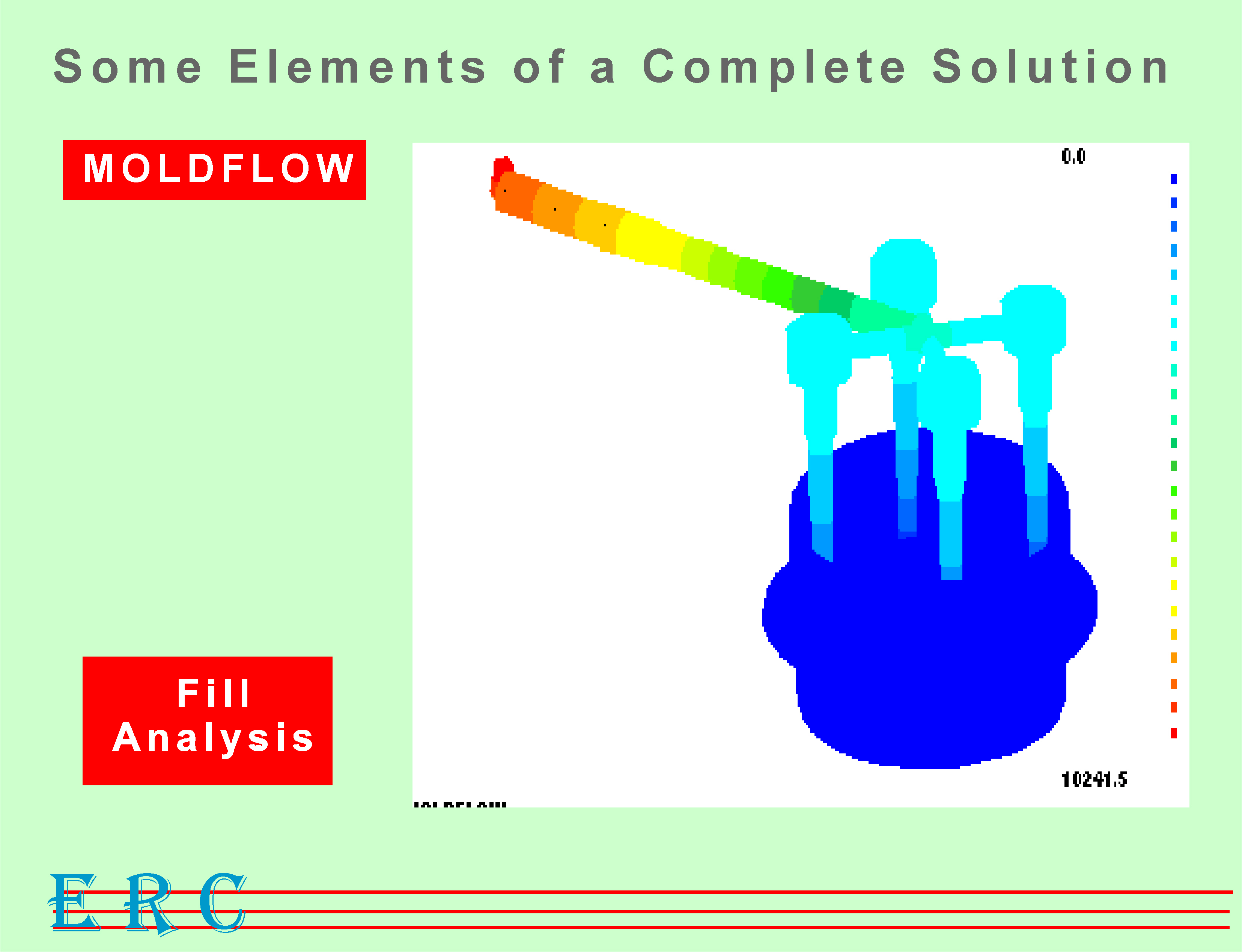

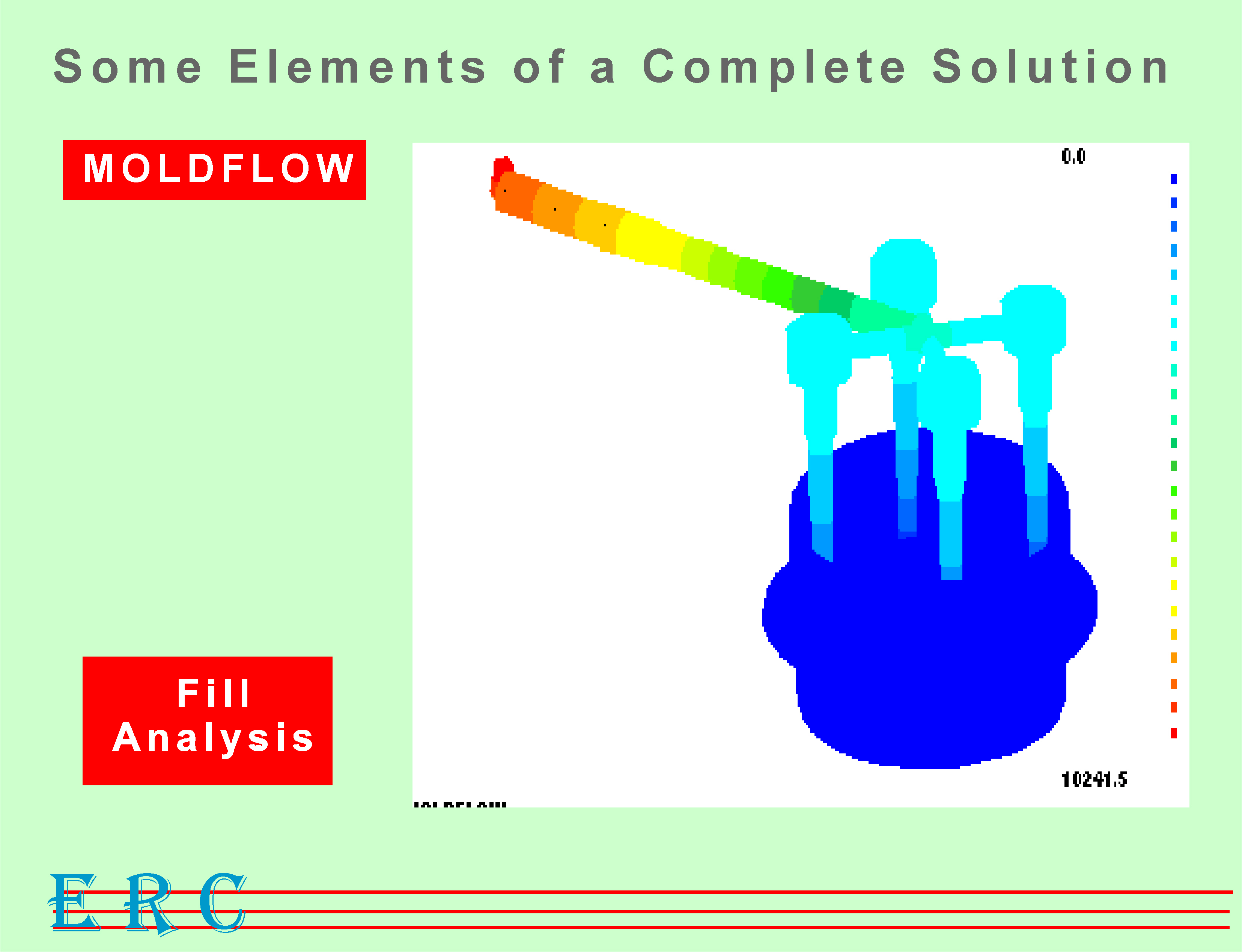

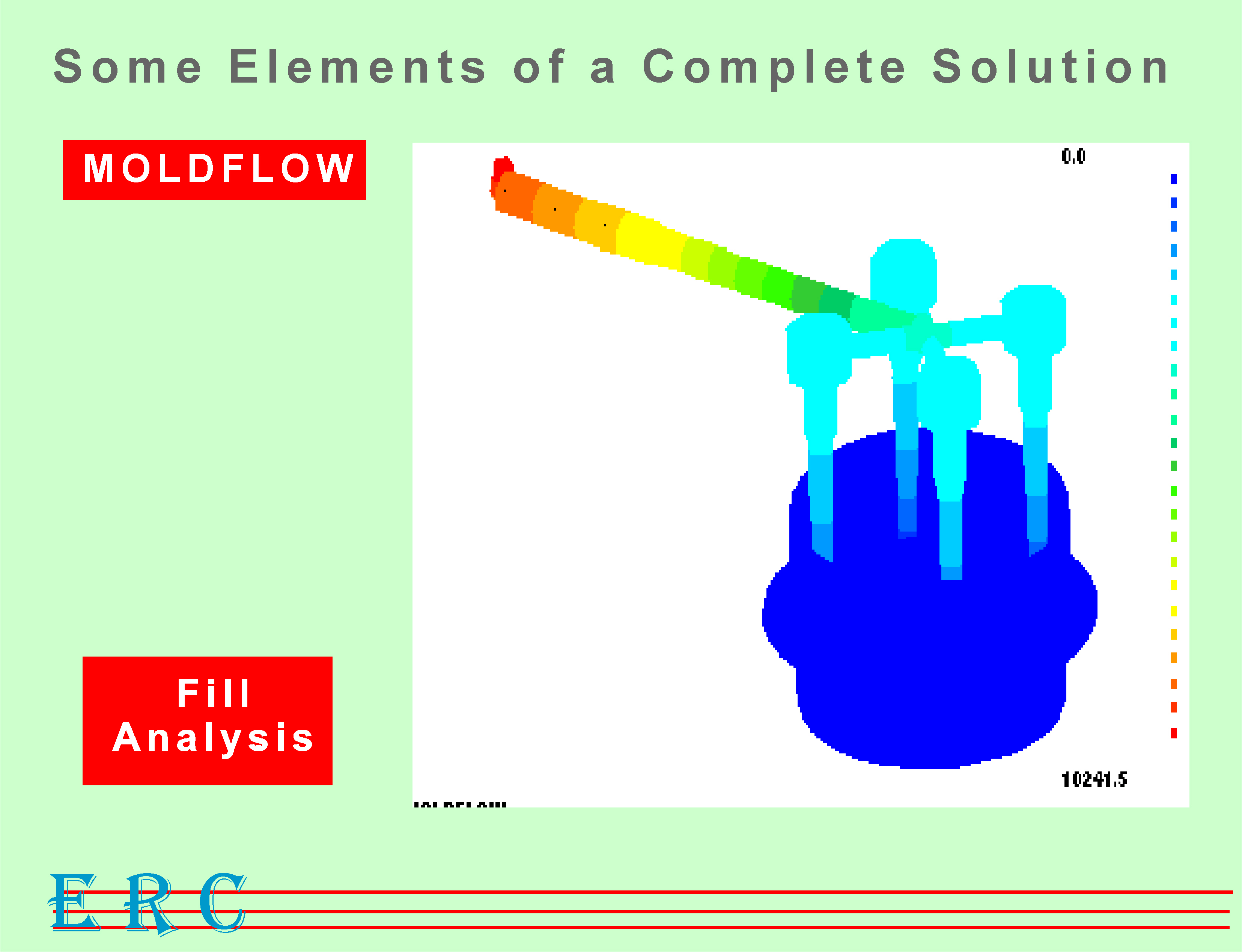

We plan to work closely with Precision Plastics Engineering, who have the ability to model the injection molding process using MOLDFLOW. These modeling tools provide us with an ability to verify whether an individual part or a sub-system meets the intended functional design specifications and also verify whether it can be manufactured.