Full Six Sigma implementation at the everyday detail level is easier said than done. The first sign of Six Sigma implementation is a scramble to pressure suppliers to achieve Six Sigma quality levels on existing parts for current products. While not without some benefit, this effort roughly corresponds to parts of Steps No. 5 and 6 of the Six Steps to Six Sigma. Full implementation of all Six Steps, however, must be done throughout product development.

We need to understand and require knowledge the following:

- Sensitivities of end-product requirements to key part/assembly characteristics

- Ability of manufacturing processes to create those key characteristics

- Consistent way to communicate variability requirements to our suppliers

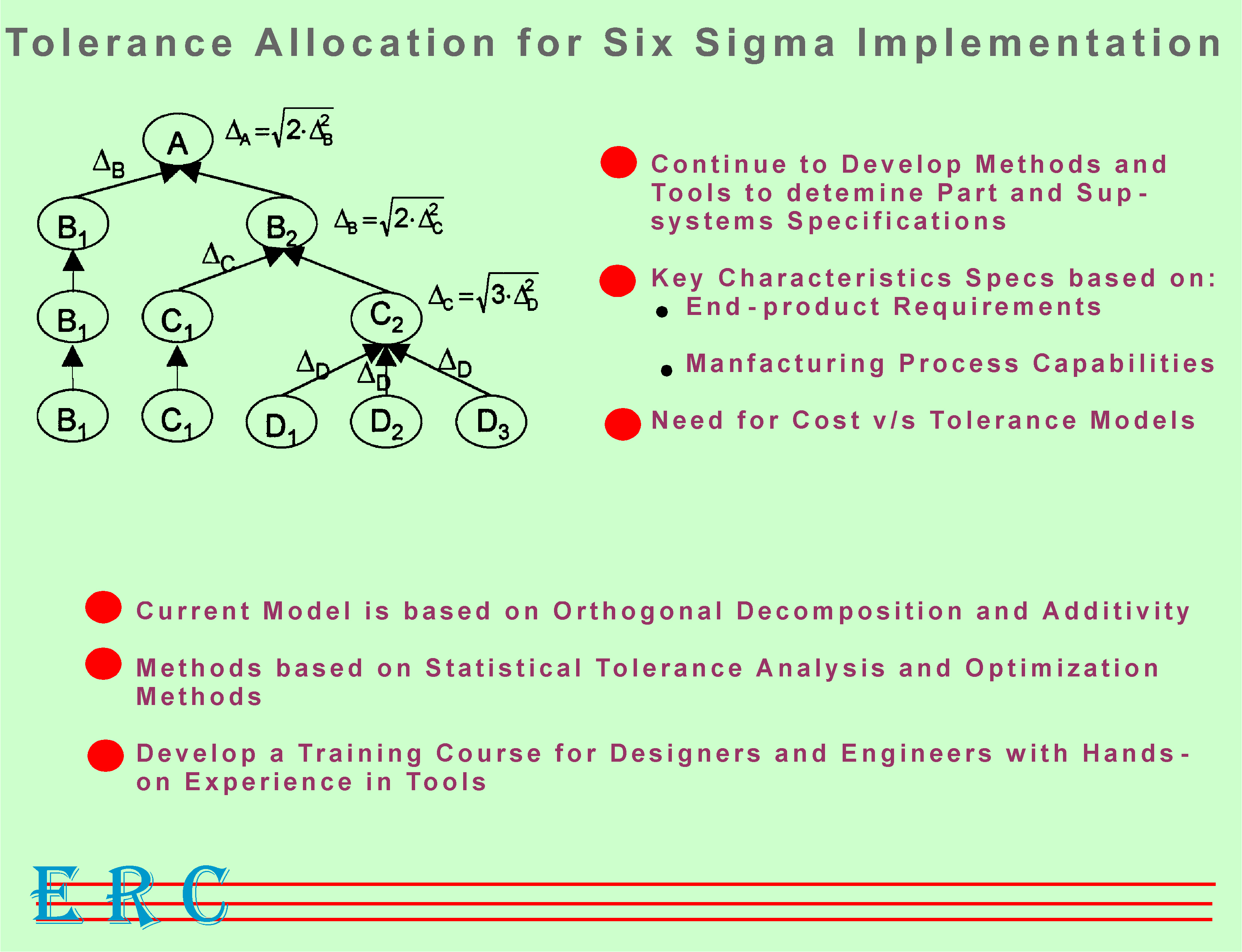

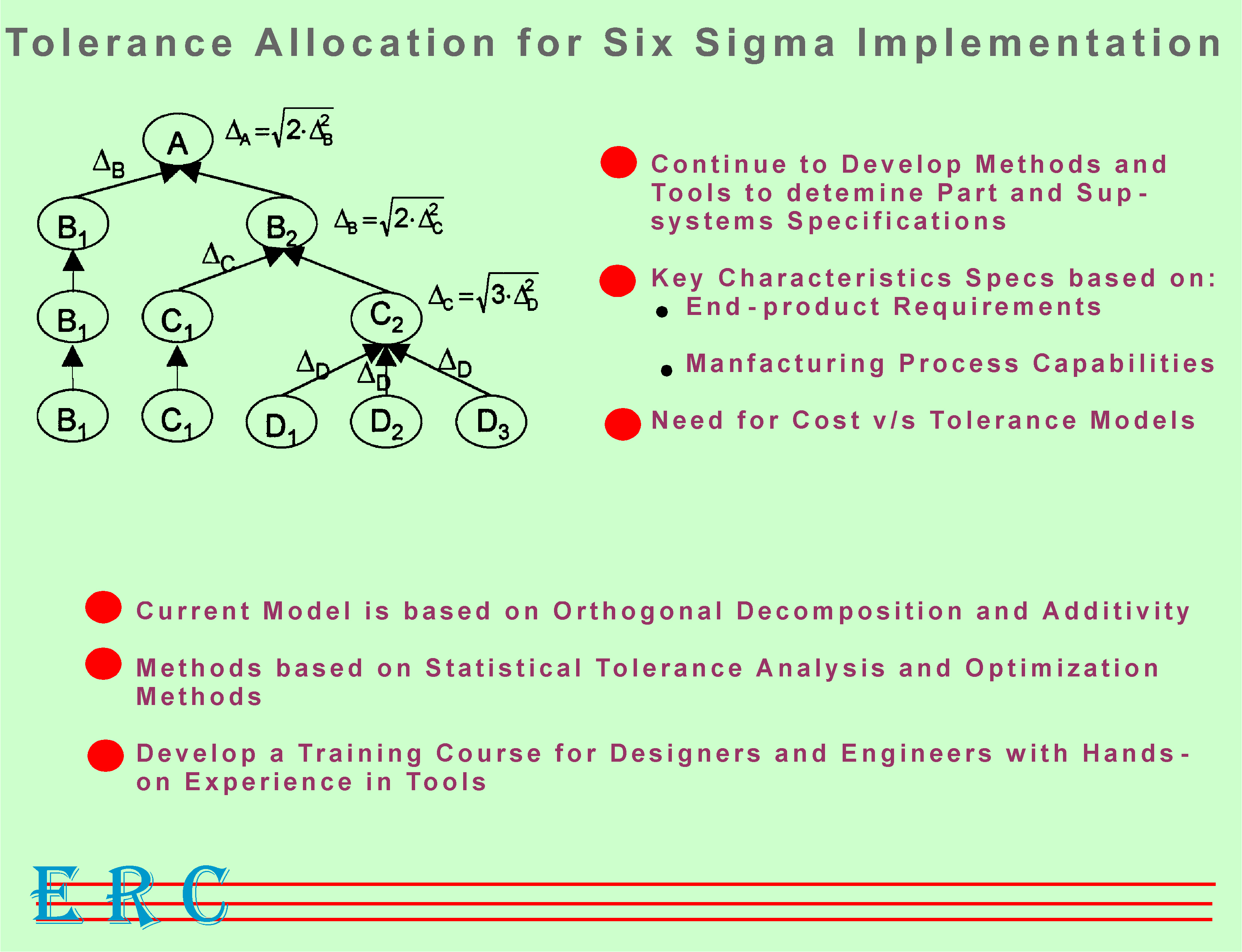

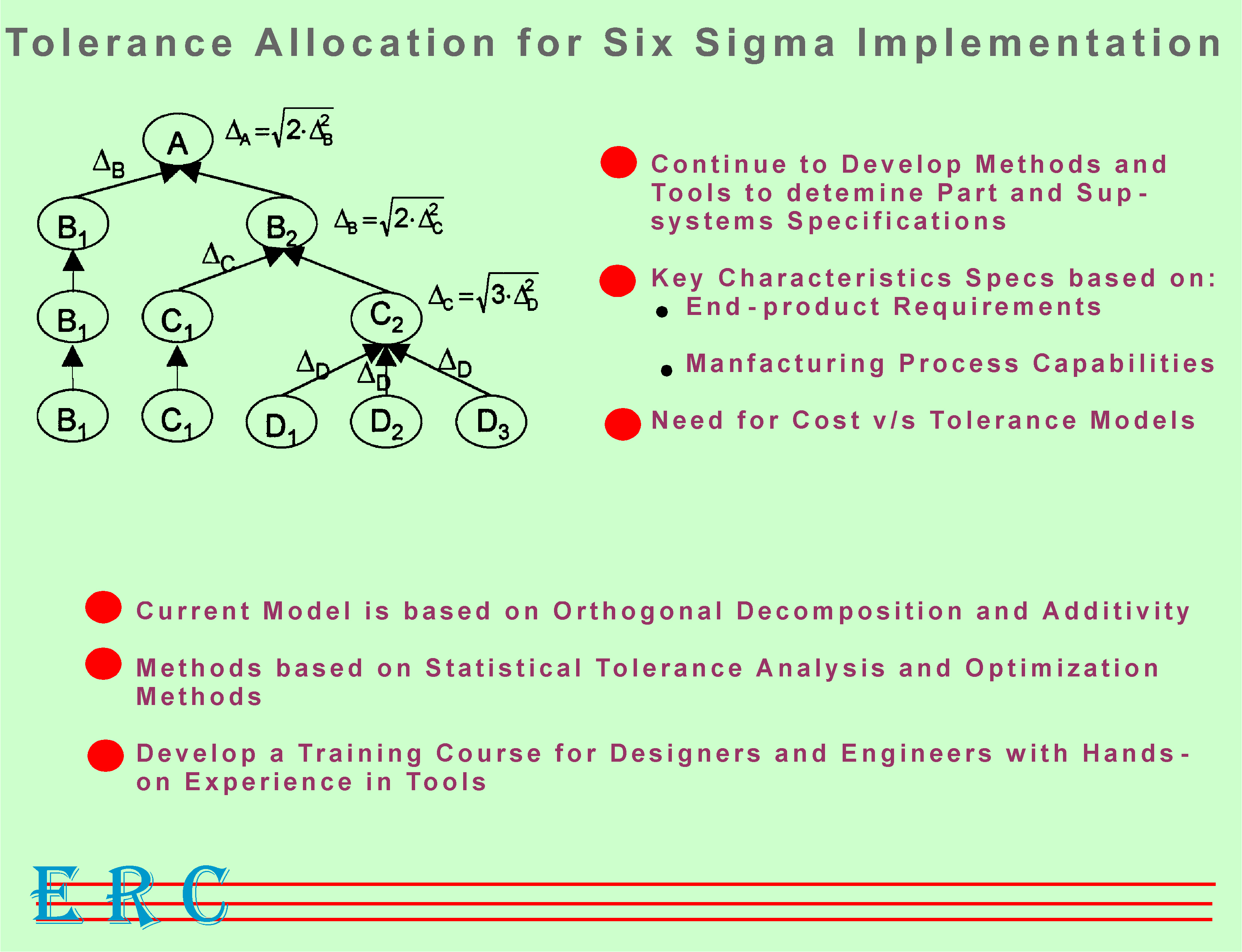

Our EWO effort addresses this need and focuses on developing methods and processes that enable engineers to allocate tolerances on sub-systems and individual parts based on customer requirements and manufacturing process capabilities. Mike Poccia∆s current model is based on Orthogonal Decomposition and assumes linearity in Systems. We plan to extend the methodology to non-linear systems.

We are currently developing a training course for engineers and designers in the use of this method where they will be able to get hands-on training in the tools we develop.